TDI PACKSYS HEADQUARTERS

974 Corporate Woods Parkway, Vernon Hills, IL 60061

P: 877.834.6750 | F: 847.620.0676

© 2025 TDI PACKSYS. All Rights Reserved. | Web Design by Connective

TDI Packsys GP Bulk‐Flow X‑Ray Inspection Systems deliver unmatched contaminant detection for a wide range of harvested and industrial products – everything from nuts, beans, and grains to plastic resins and rubber pellets. A high-precision air-blast rejection system removes even the tiniest foreign bodies cleanly, minimizing product waste and downtime.

These systems use advanced artificial intelligence to find low-density and organic contaminants. They can detect wooden sticks, shells, and holes caused by pests. They can also spot hollow or oddly shaped items that regular metal detectors might miss.

Their wide-belt and vibratory feeder spreads the product into a thin layer. This maximizes x-ray beam exposure, improves image clarity, and reduces false rejects.

GP bulk x-rays can inspect up to 40,000 lbs per hour. They do this without losing sensitivity, making them great for high-volume work in cereal mills, snack-food plants, spice blenders, and more. Whether you’re inspecting fruit, coffee beans, frozen snacks, or industrial materials, these machines maintain line speed, ensure food safety compliance and protect your brand’s reputation.

Don’t risk the quality of your harvested goods next season – allow the GP series industrial x-ray inspection systems from TDI Packsys to do the hard work for you, providing the absolute best in removal of foreign materials for your process.

Bulk-flow food x-ray detection systems are excellent for handling high-volume products. They are particularly effective with free-flowing items such as dried fruits, snack mixes, cereal grains, and spices. These systems ensure precise detection of contaminants at high speeds, preserving product quality without disrupting the production process.

The systems offer gentle handling while efficiently identifying foreign materials, making them perfect for delicate items like candy, chips, pasta, and frozen fruits and vegetables. This helps protect both product integrity and brand reputation.

Bulk-flow food x-ray machines are also well-suited for challenging applications like nuts, nuts-in-shell, coffee beans, seafood (such as shrimp and scallops), and pet food kibbles. Using advanced detection technology, they can find both heavy and light contaminants in food inspection applications. This offers a flexible solution throughout the food industry.

Each system comes with the training, service and support your staff needs – TDI Packsys is with you every step of the way to make sure you are 100% satisfied. Additionally, TDI Packsys provides annual testing, certification and maintains FDA registration to ensure your system remains in complete and continual compliance with all applicable regulations. Trust us with your industrial x-ray inspection needs.

When you need superior metal‑detection sensitivity or the power to find non‑metallic contaminants – bone, stone, or even glass – only x‑ray inspection delivers. Cutting‑edge systems from TDI Packsys pinpoint the smallest hazards so you can guarantee product safety and integrity every time.

Our diverse lineup of industrial x‑ray machines combines advanced features. High‑quality equipment and customized technologies deliver unrivaled safety, accuracy, and uptime. No other provider matches the quality, reliability, and overall value that TDI Packsys brings to your inspection process.

See our systems in action with free, no‑obligation validation testing tailored to your products and contaminants. We recreate your exact production environment, test your samples alongside our certified set, and deliver detailed photos, videos, and a formal sensitivity report – so you can confidently choose TDI Packsys for your inspection needs. Contact us today.

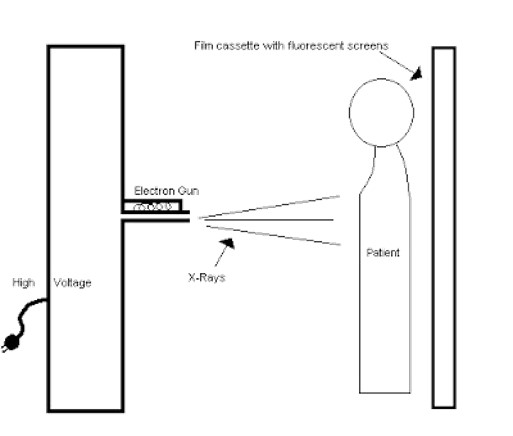

X-ray inspection systems work by producing beams of high frequency electromagnetic radiation (x-rays) in a generator. These beams are then directed at a desired target, which will absorb some of the rays while allowing others to pass through. On the opposite side of the target from the generator sits a detector which then reads the EM waves that make it through the target.

The higher the density/larger the size of the product, the less radiation will pass through. The result is an image produced by the detector which details the high and low density areas throughout the target. This is the same principle seen when making shadow puppets on a wall. Some light is blocked by the puppet, and the resulting shadow gives detail on the shape of the puppet. With x-rays, that detail is also internal.

The main difference between metal detectors and x-ray inspection systems is in the methodology of how each machine inspects for foreign materials. Metal detection relies on conductivity to locate stainless, ferrous and non-ferrous metals in product, while x-ray uses density differences between the product and foreign bodies to perform inspection. X-ray technology allows for a far greater range of foreign materials to be detected, including metal, glass, stone, bone, rubber, gasket (both metal detectable and non-metal detectable), plastic, and various other mid and high-density items. As a general rule of thumb, x-ray inspection systems are able to detect contaminants at a much smaller size than metal detectors.

Some products are limited by their composition and packaging with which inspection systems can be used. Products with metallic packaging, such as those with metallized foil, cannot be accurately inspected with a metal detector, and require the use of an x-ray system. The best way to determine which option is best for your application is to receive a consultation or free, no-obligation validation testing. We can test your exact product on a variety of different systems using certified test cards, or foreign material samples you provide, to offer you a formal report on the capabilities and expected performance of each type of technology. At TDI Packsys, we believe validation testing on your specific products is an integral step in choosing the right system for your needs.

No PPE is required to be worn while operating x-ray inspection systems from TDI Packsys. The use of lead lining and protective curtains in the x-ray mitigates radiation from the generator, allowing only a fraction of the radiation used in inspection to exit the system. The FDA regulates these systems, and has set a standard of 5 μSv/hour as the safe level of radiation. X-ray systems from TDI Packsys emit doses of less than 1 μSv an hour, well below the FDA allowable limit. Every day, we are exposed to background radiation naturally produced by the sun and various environmental factors. Each year, the average person is exposed to 2,400 μSv of this background radiation, a higher dose than you would get standing next to an active x-ray inspection system for more than 3 months straight.

Name | GP Bulk Flow X-Ray Inspection System |

Model | XR-4080GP |

X-Ray Tube | MAX 80kV, 210W |

Inspection Width | 400mm (15.75 in) |

Inspection Height | 50mm (1.97 in) |

Detection Sensitivity (without product) | SUS304 Φ 0.3mm SUS wire Φ 0.2mm Glass (soda lime) Φ 1.0mm Ceramic Φ 1.0 mm |

Conveyor Speed | 10 – 120 meters / minute |

Conveyor Maximum Load | 25 kg |

Display Screen | Full-color TFT 17″ Touch Screen |

Operating System | Windows 7 |

Connectivity | USB and Ethernet |

Product Management | Complete production log |

Image Management | Save/Print/Analyze |

Parameter Adjustment | Auto or manual programming |

Power | 220V, Single Phase, 15 amp |

Construction | SUS 304 |

IP Rating | 67 (wash down for tunnel/conveyor) |

Temperature Control | Industrial Air Conditioned |

Protection | Removable protective curtain |

Operating Temperature Range | 0 – 40°C |

Operating Humidity Range | 30 – 90% |

X-ray Ambient Emissions | Less than 1.0 micro-Sievert per hour |

TDI PACKSYS HEADQUARTERS

974 Corporate Woods Parkway, Vernon Hills, IL 60061

P: 877.834.6750 | F: 847.620.0676