For all types of manufacturing operations, quality is a high priority. But within the food packaging industry, ensuring quality is especially important. Foreign contaminants that make their way into food products can be extremely dangerous to consumers and result in expensive, brand-damaging recalls for food companies.

The FDA Food Guidance Regulation document clearly states the implications of foreign objects in food. Common types of injuries that can be caused by foreign objects include:

- Lacerations of the mouth

- Lacerations of the throat

- Lacerations of the intestine

- Damage to the teeth

Additionally, particularly small contaminant fragments can seriously injure infants, seniors, as well as surgery patients.

In the food production industry, metal is one of the most frequently found contaminant materials in food. Unfortunately, metal can enter food products at all stages of the processing of food. This may happen due to the construction of the machinery, handling equipment, or other utensils used during the process. If a part of a food packaging machine becomes loose during production, it may fall off and enter the food product. Not only that, but food packaging equipment that frequently grinds together may produce small metal fragments.

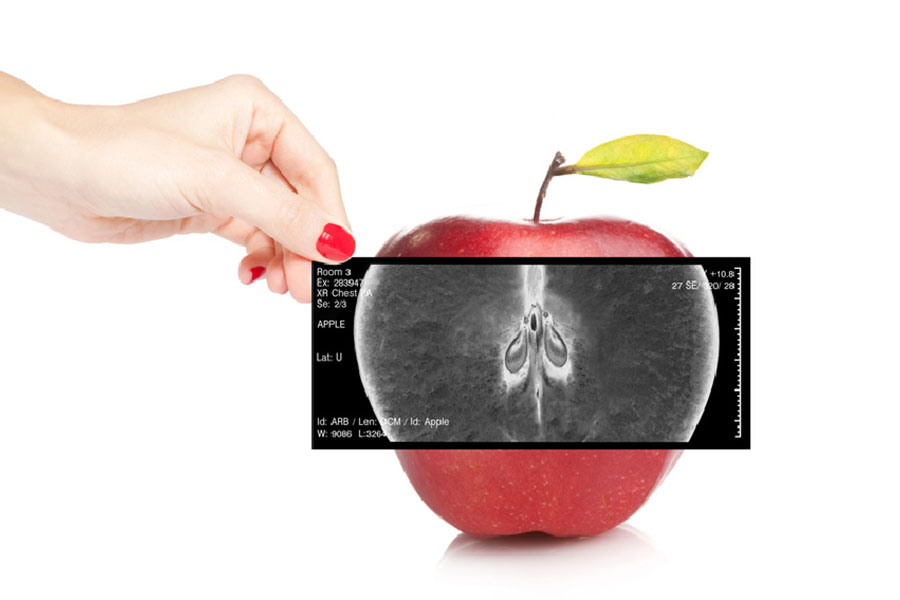

Fortunately, food inspection systems such as X-ray food inspection equipment and metal detectors can easily catch these contaminants. Metallic contaminants that a metal detector can pick up include ferrous contaminants, non ferrous contaminants, and others depending on certain conductive properties of the contaminant.

Food inspection systems, like x-ray machines or metal detectors, allow packaging companies to thoroughly inspect food products before they are distributed to the public. Nowadays, a visual check just doesn’t cut it. This is because when just looking at a complex machine, missing or damaged parts may not be apparent.

Because food inspection systems can detect different sizes of metal, manufacturers should find one that will be able to meet their requirements. Depending on the packaging options and flexibility, the type of inspection system will vary.

Proper food inspection isn’t all packaging companies have to worry about. While safety is a top concern, consumer wants and needs are considered too. For example, packaging companies are trying to make packaging less wasteful, because that’s what consumers want. In fact, 52% of people worldwide consider making a purchase partially because the packaging reflects a positive social and environmental impact.

The food packaging industry has a lot of responsibility in both pleasing consumers and ensuring their safety. The importance of food inspection equipment should be considered throughout the food packaging industry and manufacturers should ensure the equipment is doing an exemplary job.